- Home

- Rifle

- AR15 / SR15 Upper Receiver

- Forward Controls Design Bolt Carrier Group Phosphate

Forward Controls Design Bolt Carrier Group Phosphate

$225.00

Description

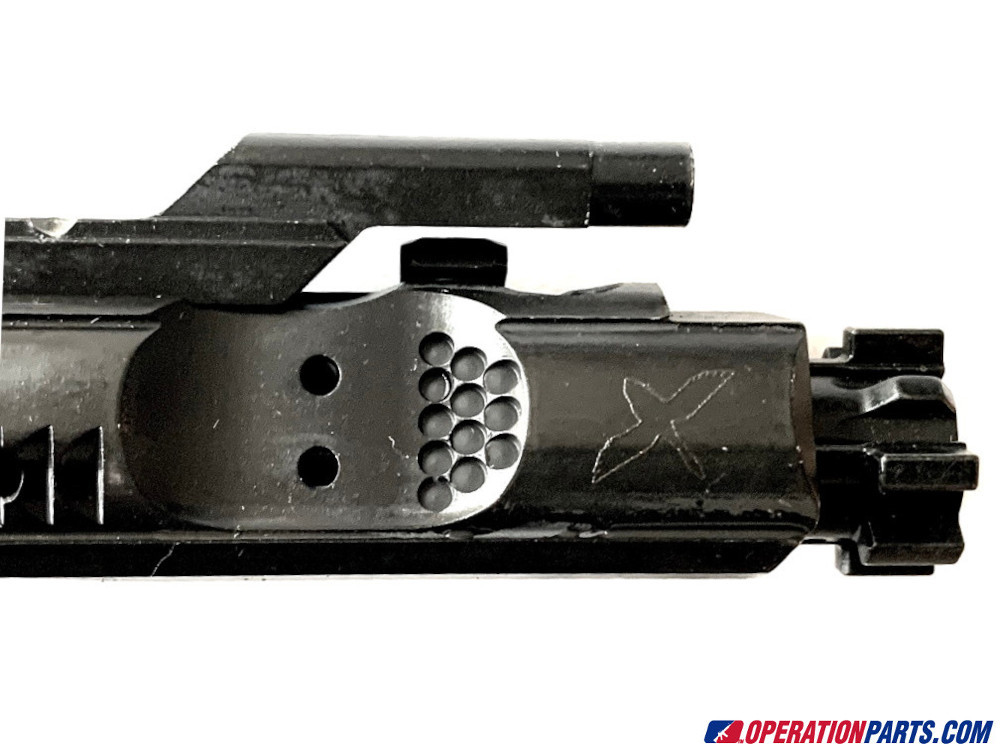

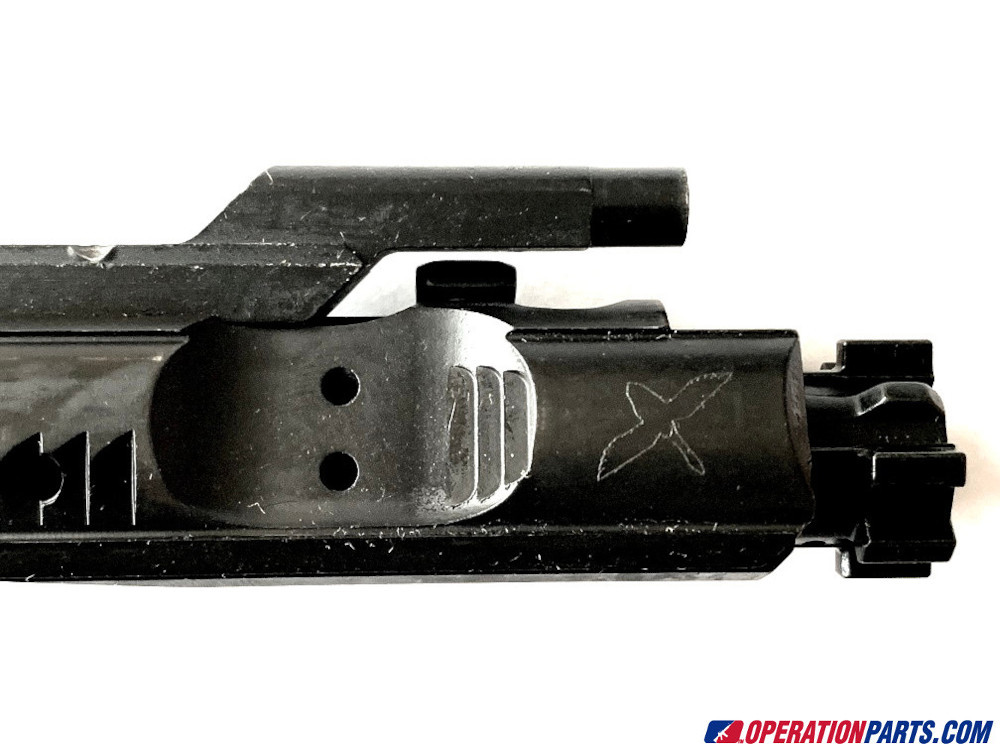

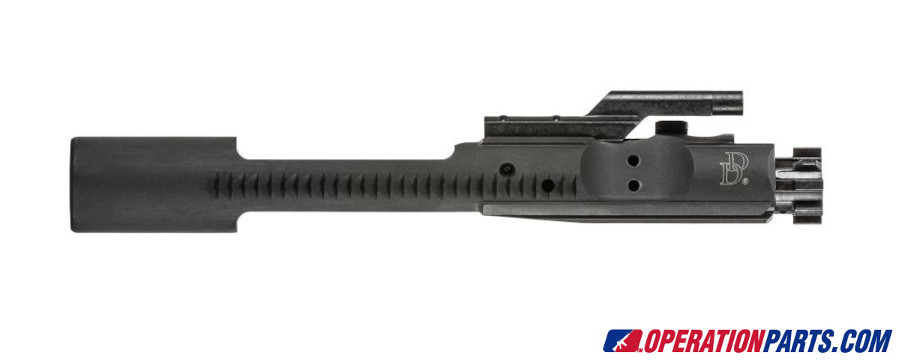

Forward Controls Design Bolt Carrier Group Phosphate (SBCG-P)

It is our view that the factory M16 carriers are very good, and improvements over them would be hard to come by. Modern coatings have made them easy to clean and quite slick, which we can appreciate. NP3 coating is rather expensive and time consuming, which limits NP3 SBCG’s production to about 200 units a year. SBCG-P is identical to the NP3 SBCG, save for the coating of the bolt, carrier and SCP (SOTAR Cam Pin). SBCG-P is manganese phosphated, and uses black nitrided SCP.

Removal torque spec is 55-100 in-lb

Testing consistently found removal torque of YFS screws averaging around 76 in-lb, with the OCKS consistently at 132 in-lb.

Since we’re so keen on the gas key’s staking to ensure its immobility, the question of one piece carrier had come up. It is our opinion that something different isn’t always something better. Gas keys can crack, and be dropped and damaged, debris or primer can find its way into the gas key. Our view is based on reality, not a theory, as all of these have happened. A conventional carrier with a separate gas key can simply have its gas key replaced, which is impossible for any one piece carrier.

Each SBCG has its firing pin protrusion checked, gas key torqued and staked, and is individually test fired. SBCG will ship as is, having been slightly lubed and dirtied by the test firing procedure.

* Sprinco 5-Coil Heavy Duty Extractor Spring

* Black Insert

* SBCG carriers are 8620 steel and machined to USGI specifications. The M16/M4 carrier includes a mil-spec gas key. The gas key is heat treated per TDP specifications and NP3 coated. The gas key is secured to the carrier via OCKS (Optimized Carrier Key Screws), torqued to spec values, and properly staked.

* Manganese phosphate coated.

![]() WARNING:

WARNING:

This product can expose you to chemicals including arsenic, which is known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

Your question will appear on the site once someone answers it.

- Reviews (0)

- Questions (0)